七诺洁净

We are dedicated to providing our customers with high-quality products and professional services,Welcome to negotiate, and we hope to work together to create a better tomorrow!

我们竭诚为客户提供优质的产品和专业的服务,欢迎您前来洽谈,愿我们一起携手合作共创美好的明天!

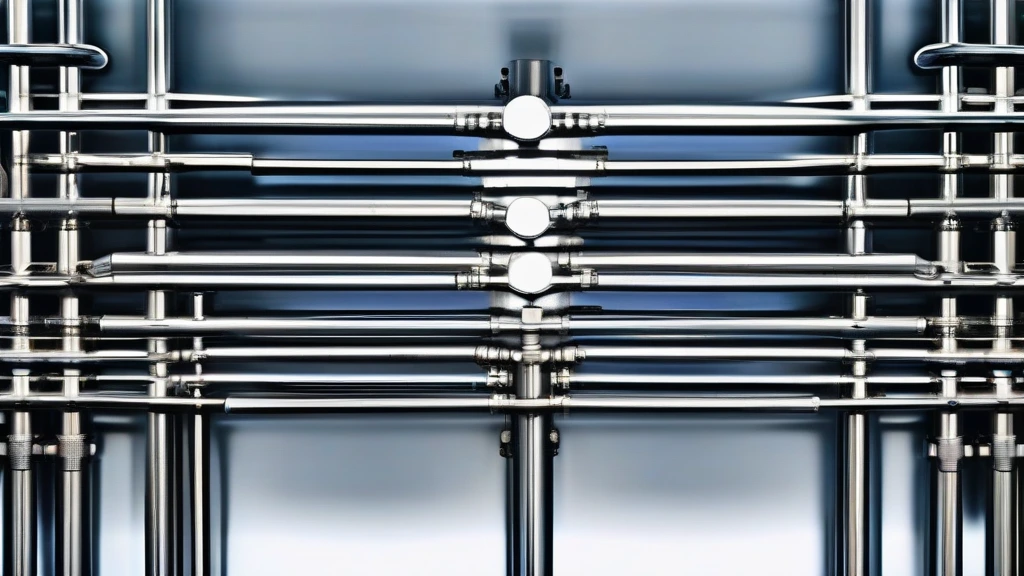

Professional research and development, production, and sales of ultra-high purity gas transportation materials

专业研发、生产和销售超高纯气体输送材料

We have a professional and experienced production and research and development team, and our products are widely used in industries such as semiconductors, photovoltaics, biopharmaceuticals, electronic grade chemical plants, high-voltage hydrogen energy, and automation components.

我们拥有专业且经验丰富的生产和研发团队,产品广泛用于半导体、光伏、生物制药、电子级化工厂、高压氢能、自动化元件等行业。

We specialize in producing high-precision stainless steel pipes (cylinder pipes, BA pipes, EP pipes, high-pressure pipes) and other alloy related products. We have a two roll cold rolling mill, a precision three roll cold rolling mill, a precision inner core cold drawing machine, a precision straightening machine, an inner and outer polishing machine, a pipe bending machine, etc. We also have a complete production line including an oxygen free bright heat treatment furnace, a dust-free bright production line, a negative ion pure water cleaning line, a dust-free packaging workshop, etc. We mainly produce various ultra precision, ultra clean, ultra bright, high-strength seamless stainless steel pipes and high-temperature alloy pipes. We also have high-purity precision cleaning equipment and a complete EP equipment assembly line, mainly producing high-purity gas tubes BA, EP TUBE, In semiconductors LCD、 Industries related to solar energy, medical pharmaceuticals and biology, food, automation equipment, etc. We always adhere to and implement the business philosophy of "winning the market with integrity, exploring the market with diligence, consolidating the market with technology, and ensuring the market with quality". We regard "technology, talent, and brand" as important factors for enterprise development, and "pursuing customer satisfaction and establishing brand core values" as our business philosophy. We use innovative technology research and development and professional services to achieve a better future.

我们专业生产高精密不锈钢管(气缸管、BA管、EP管、高压管)及其他合金相关产品, 拥有两棍冷轧机、精密三辊冷轧机、精密内芯冷拔机、精密矫直机、内外抛光机、弯管机等, 并且还有无氧光亮热处理炉、无尘光亮生产线、负离子纯水清洗线、无尘包装车间等全套生产流水线,主要生产各种超精密、超洁净、超光亮、高强度的无缝不锈钢管和高温合金管。 同时拥有高纯净精密清洗设备及完整的EP设备流水线,主要生产高纯度气体管BA,EP TUBE, 在半导体、LCD、太阳能、医疗制药及生物、食品、自动化设备等相关行业。 我们始终坚持并执行"用诚信赢得市场,用勤奋开拓市场,用技术巩固市场,用质量保证市场"的经营理念,将"科技,人才,品牌"作为企业发展的重要因素, 以"追求顾客满意,树立品牌核心价值"作为企业经营宗旨,用创新的技术研发和专业的服务成就美好未来。

We are dedicated to providing our customers with high-quality products and professional services,Welcome to negotiate, and we hope to work together to create a better tomorrow!

我们竭诚为客户提供优质的产品和专业的服务,欢迎您前来洽谈,愿我们一起携手合作共创美好的明天!

Seamless,Semi-seamless and Welded tubes and pipes are manufacturing throughout state art of equipment, unique technologies and strict quality assurance process.

无缝、半无缝以及焊接钢管、以精密的机器制造工艺,独特的技术以及严格的质量管控流程,来确保产品品质。

产品特点:采用316L材料,主要运用于高纯气体生产,生物制药、光伏、LCD及芯片半导体等对洁净度要求高的行业。管子按照ASTM A269/A270标准生产,对于洁净度要求超高的环境,管子需在无尘室进行氮气吹扫和包装以满足要求。内表面粗糙度可控制在Ra0.5μm以下。

产品特点:采用316L/316L(VIM+VAR)材料,主要运用于高纯气体生产,生物制药、光伏、LCD及芯片半导体等对洁净度要求高的行业。 管子按照ASTM A269/A270标准生产,对于洁净度要求超高的环境,管子需在无尘室进行氮气吹扫和包装以满足要求,内表面粗糙度可控制在Ra0.2μm以下。

产品特点:采用316L/304材料,气缸管是一种通过冷拔或热轧处理后的一种高精密的钢管材料。由于精密钢管内外壁无氧化层、承受高压无泄漏、高精度、高光洁度、冷弯不变形、扩口、压扁无裂缝等有点所以主要用来生产气动或液压元件的产品,使用不锈钢材质来做气缸管具有产品设计轻小和使用寿命长的特点。因为不锈钢材质具有高强度和耐腐蚀性,相对铝、铁等材质而言,由于强度高,无磁性,因此可以设计比铝铁材质轻薄,可以降低产品的大小和重量,用于迷你气缸比较多.是轻便自动化设备的首选。不锈钢气缸管内外粗糙度可达Ra0.2-0.4μm,内外径公差最高带可达0.03mm;规格从内径Φ3--Φ100mm,壁厚0.5-8mm。

无杆气缸是指利用活塞直接或间接方式连接外界执行机构,并使其跟随活塞实现往复运动的气缸。这种气缸的最大优点是节省安装空间,分为磁偶无杆气缸(磁性气缸)与机械式无杆气缸。规格从内径Φ10--Φ50mm,壁厚0.5-2.5mm,内径公差0.05以内,内表面粗糙度可控制在Ra0.4μm以下。

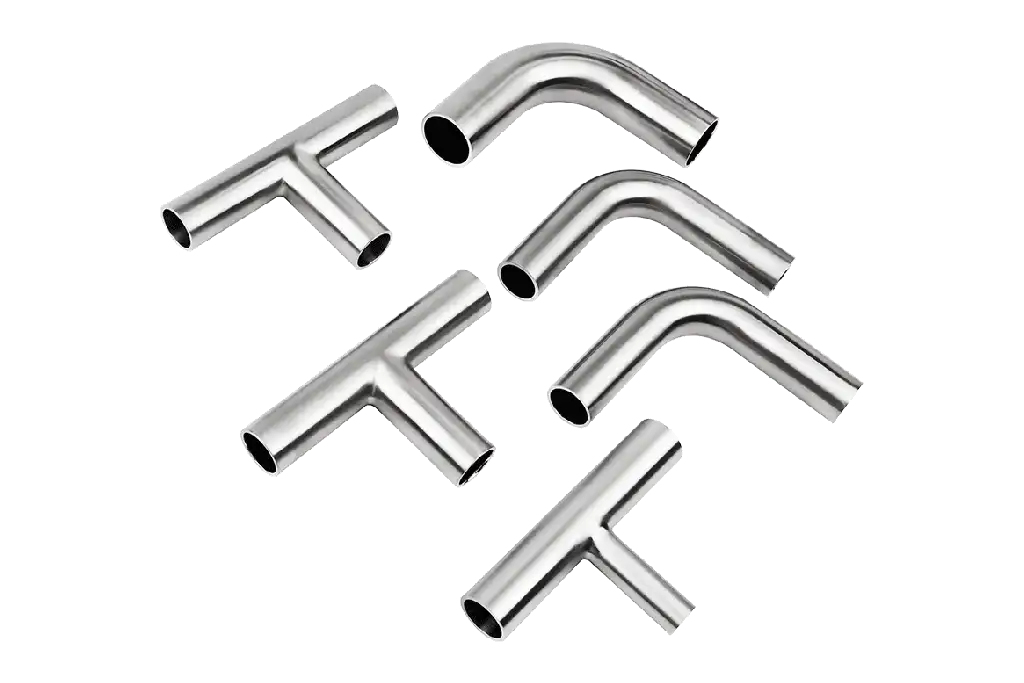

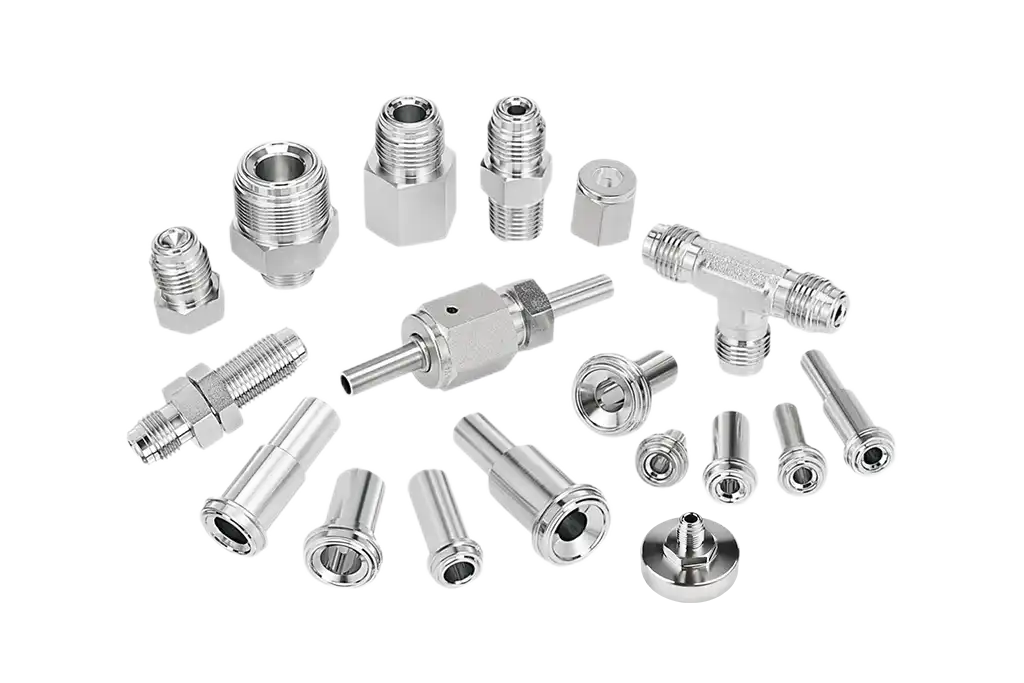

适用于超高纯度气体,半导体用(毒、腐)气体,满足超大规模集成电路的工艺气体要求。

适用于超高纯度气体,半导体用(毒、腐)气体,满足超大规模集成电路的工艺气体要求。

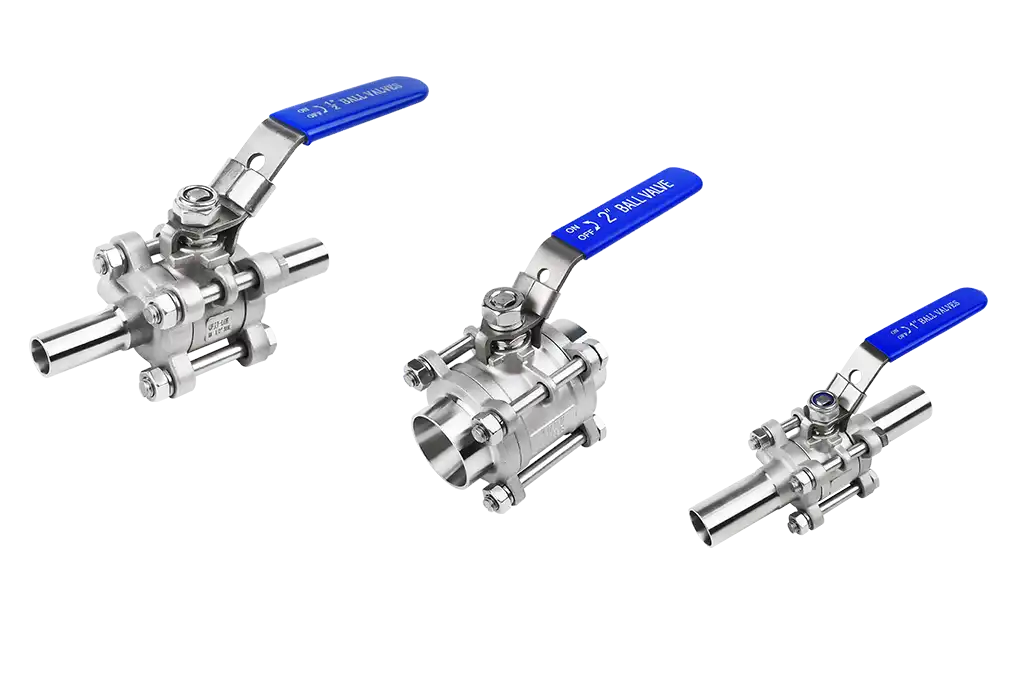

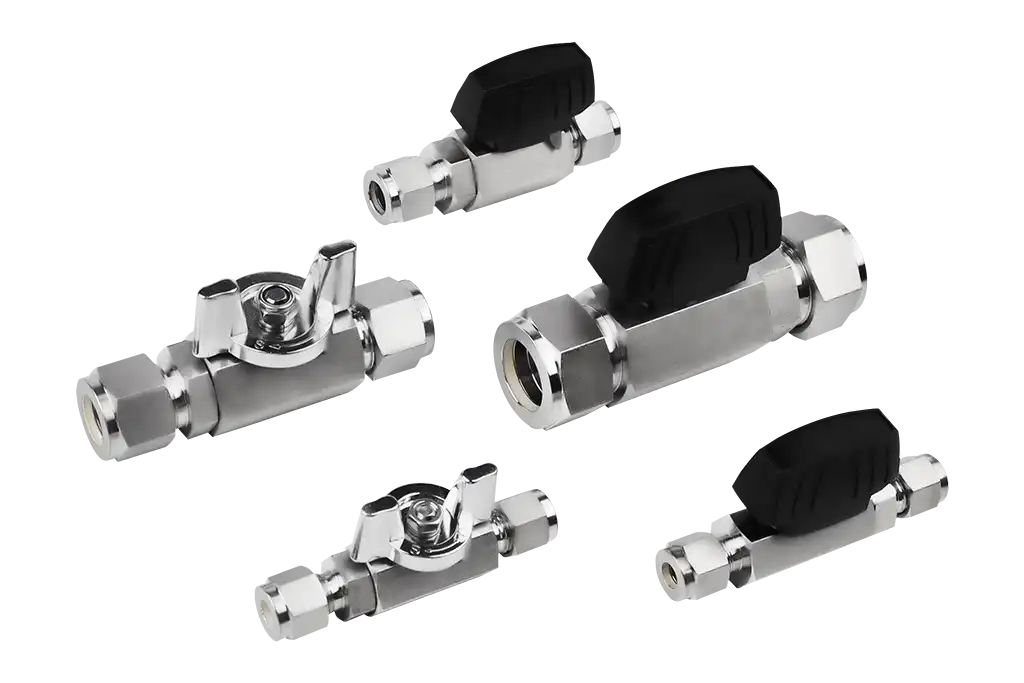

采用304/316L等不锈钢为阀体材质,具有良好的内表面处理和易清洁性,密封圈、阀芯等采用卫生标准的材料制成,广泛应用于生物制药、食品、化工等工业领域.

采用304/316L等不锈钢为阀体材质,具有良好的内表面处理和易清洁性,密封圈、阀芯等采用卫生标准的材料制成,广泛应用于生物制药、食品、化工等工业领域.

适用于,尺寸范围.

方形弯头适用于,尺寸范围

我们拥有高精密的生产设备和完善的检验设备